Single ply membranes, in certain circumstances can be punctured, but so can other flat roof waterproofing solutions – including built-up bituminous membrane systems.

Compared to other types of waterproofing, single ply membranes are easier to repair if they are damaged.

There are three key factors to minimise the risk of a puncture occurring:

- Good housekeeping on the roof

- Installation in line with up-to-date industry advice

- Following an appropriate maintenance schedule once the roof is in service

Built up bituminous roofing has a reputation for being particularly robust. Single ply membranes though can provide excellent protection with much greater flexibility.

Historically, mechanically fixed flat roof systems featuring compressible insulation could suffer from puncturing of the waterproofing membrane. Any compression of the insulation could pull the membrane taut over the fixing and cause the fixing to ‘pop through’ from underneath.

However, with plastic tube fixings and washer heads now being predominant, and rigid insulation boards being commonplace, such issues are much less of a concern.

Avoiding single ply membrane damage – good housekeeping

Any roof waterproofing solution can be damaged during installation, by following trades, or as a result of roof work and maintenance required during the membrane’s service life. When applying single ply membranes – such as the ones from the IKO Armourplan and IKO Spectraplan ranges – the following advice should be kept in mind.

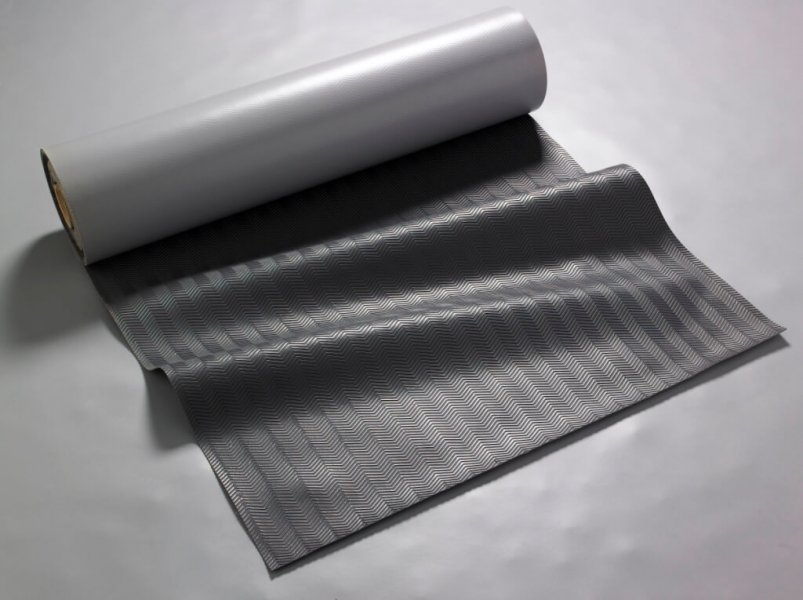

Good housekeeping is a prerequisite for any site. That starts with the correct handling of materials, and rolls of single ply should be moved and placed with care. The wrapping around rolls of single ply is not intended to protect the material on-site, so the rolls should be kept dry and clean and stored horizontally and off the ground.

Preferably, rolls should be stored indoors until ready for use on the roof. Otherwise, waterproofing sheeting can be used to protect them.

What is the best site practice for installing single ply membranes?

Once the single ply is on the roof, keeping a clear and tidy work area minimises the risk of fixings or tools being left lying around, which could easily damage the waterproofing if stood upon.

Following the waterproofing manufacturer’s advice is essential. The single ply industry also publishes guidance through the Single Ply Roofing Association (SPRA), and its Design Guide should also be consulted.

Most projects have tight timescales, and how the works are sequenced is an important consideration. Roofs are often made watertight early in the process to facilitate interior fit out, but the biggest point of risk to a single ply membrane is post-installation. Damage to a membrane is therefore rarely an issue of product quality.

Where access across an installed membrane is required, restricting traffic to limited areas is good practice for safeguarding the majority of the roof area. If necessary, following trades should be required to seek permission to cross the roof, and they should take appropriate care to avoid damage to the waterproofing, such as when erecting scaffolding.

A walkway membrane is a good example of how foot traffic can be kept to prescribed routes across the roof, protecting the waterproofing from potential damage.

Repairing a single ply membrane if it is punctured

If a single ply membrane is damaged, it is actually easier to identify the location of a hole than it is with other waterproofing types. Any hole in a single ply membrane can be pinpointed and a patch repair undertaken quickly and simply by a qualified installer. It is harder to identify similar damage on a built up bituminous roof finish.

Maintenance of an undamaged single ply membrane is not typically required, but the waterproofing should be part of routine maintenance inspections of the roof. Twice a year is a recommended interval for such inspections, or after any work on the roof which could have damaged the single ply membrane if not carried out with appropriate care.

All IKO single ply membranes offer exceptional mechanical properties, and are backed up by independent third party verification. BBA certificates, together with product datasheets, are available to download. RIBA CPD-approved seminars are also available to you, offering advice on design challenges, good and bad practise, and achieving good detailing.

For design advice, including site surveys, detailing advice, tools and calculators – or for site support for your next project – don’t hesitate to use our expert knowledge by contacting IKO Polymeric’s technical teams.